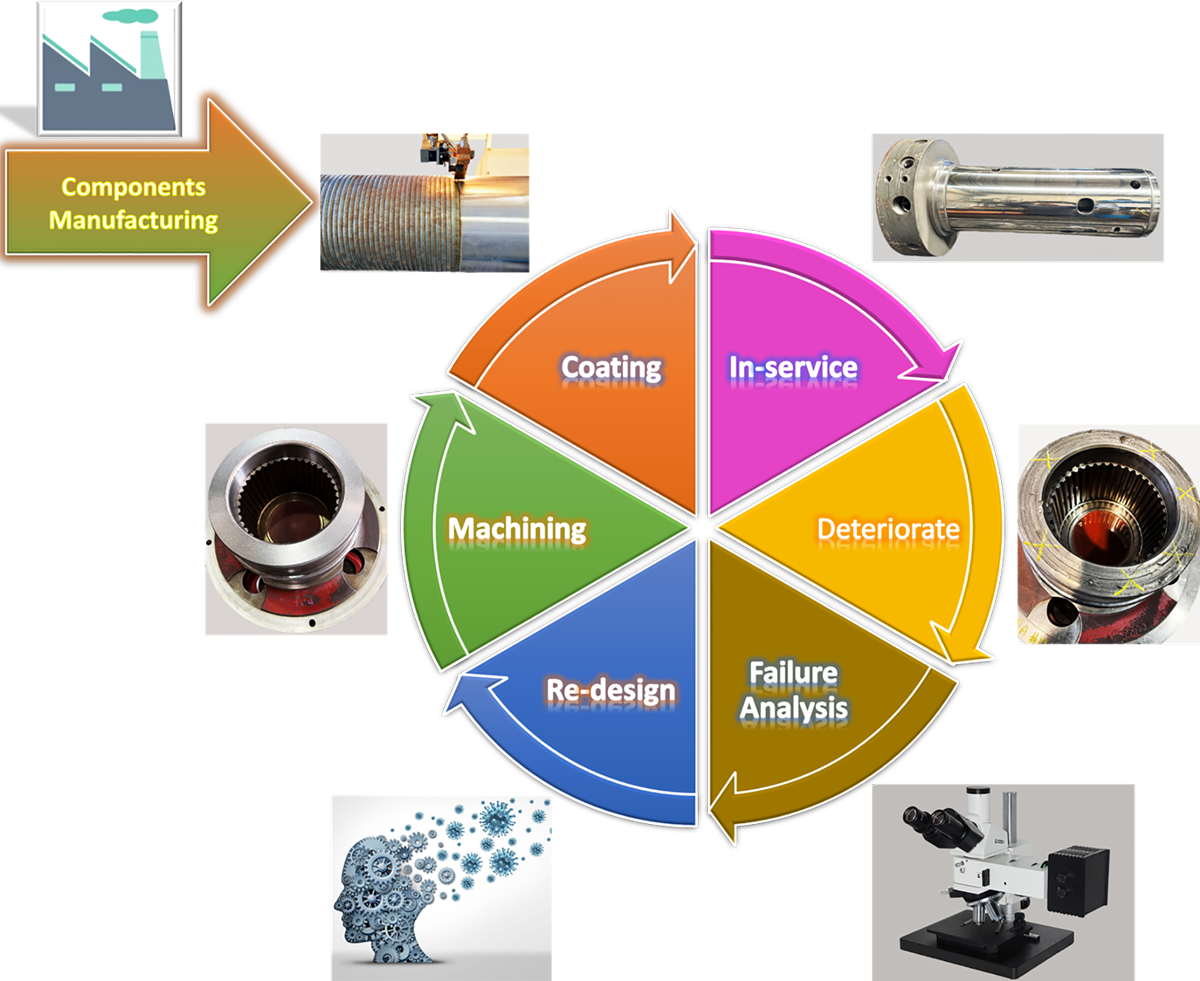

Arc Spray Engineering provides turnkey solutions for restoring mining and mineral processing components since 2011. We have many in-house repair techniques and will choose the most suitable method to restore your components and equipment to their original condition. We are committed to quality, timeline and R&D which will continue to provide excellent value for money to our clients.

Our customers are based all over Australia from one-off private customers or country workshops, to large mining, oil & gas and engineering companies.

Our continual improvement programs and R&D lab ensure we are on the leading edge in our field and will continue to be recognized as the most professional operators in Australia – Please see our range of services and send any inquiries as we welcome new challenges. We provide quality, prompt and competitively priced services.