We follow a systematic scientific approach to perform any work in our industry. The in-house laboratory equipped with metallography analysis, performance tests and qualified experts can perform high quality research work to restore your components with improved performance for your service environment. We perform failure analysis, optimize the process and perform various test to find the best solutions.

Services

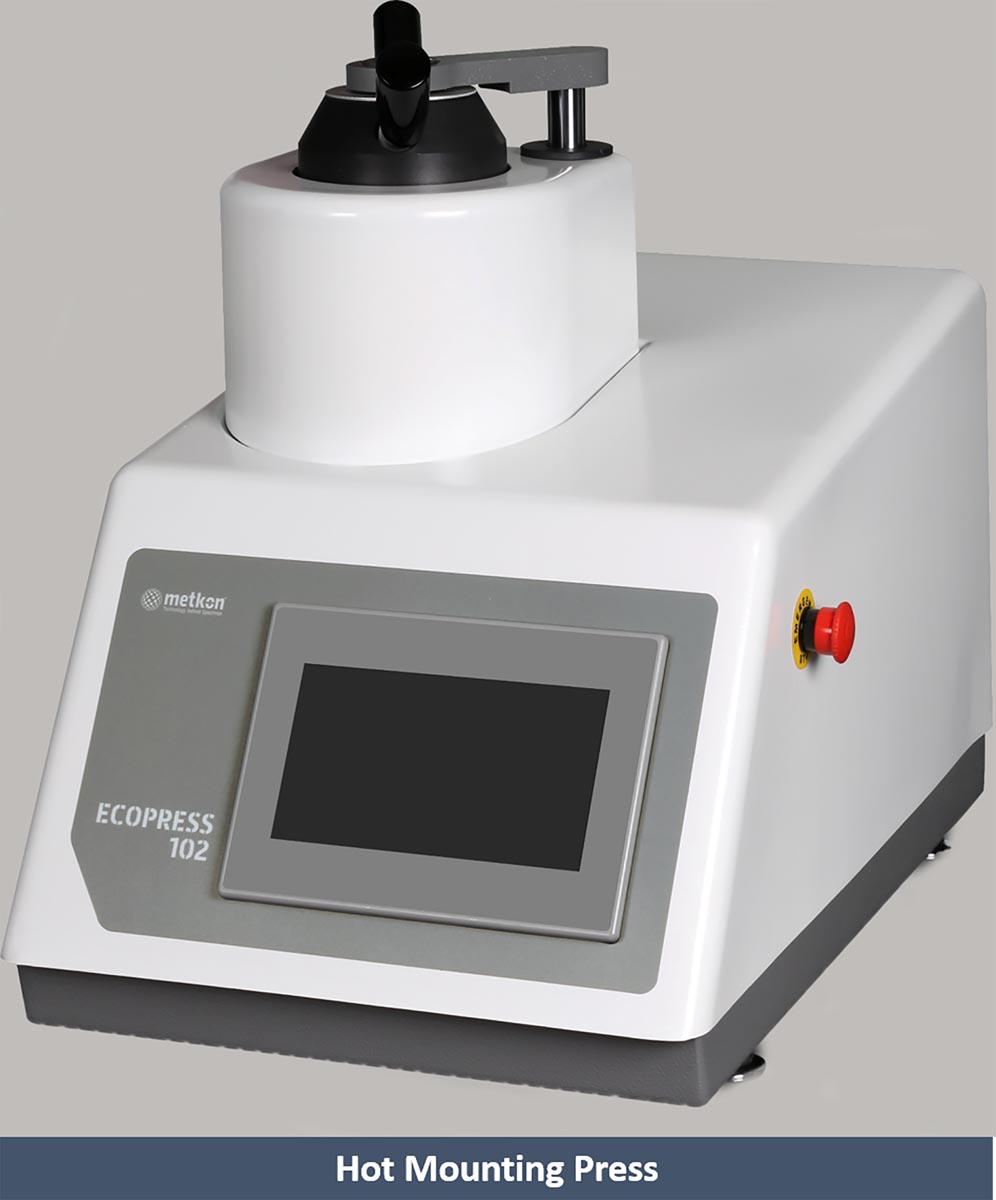

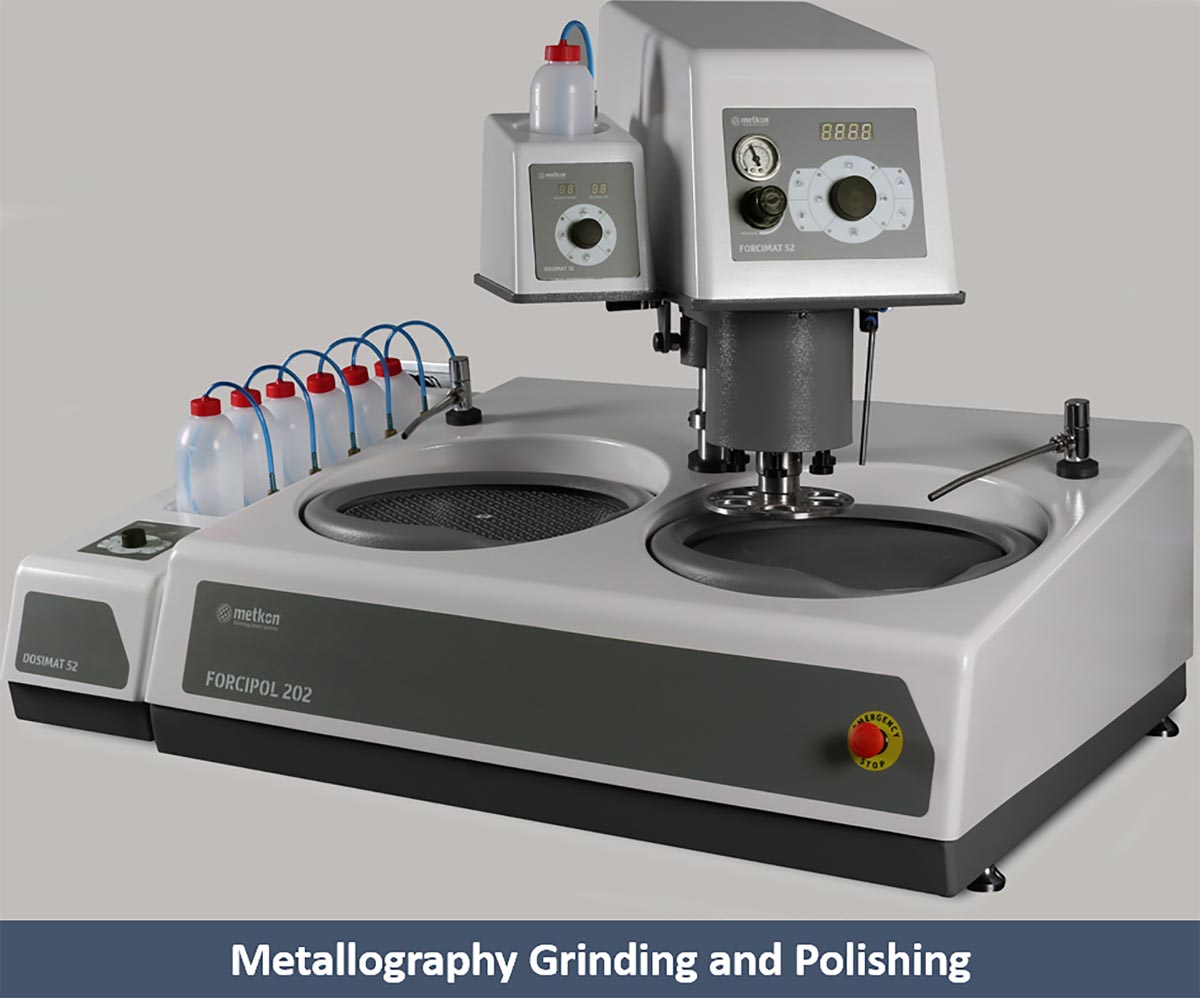

In house Research and Development laboratory

Failure analysis

We inspect and analyse the cause of the failure before hypothesising the solution to avoid any further failure in the components.

For an example, we perform NDT techniques to identify the nature of defects such as cracks, porosity and analyse the fracture surface. We quickly perform chemical composition and metallography analysis to identify any change in microstructural morphology and phase which could cause the failure.

Optimize the process and materials composition

Based on the failure analysis, we work through the materials required for restoring the components for improved performance such as wear, corrosion, erosion-corrosion and galling resistance. Based on the requirements, we select the process from the range of equipment available in our workshop. We optimize the process condition to achieve desired coating thickness with minimum/no porosity and good metallurgical bonding with the substrate.

Performance testing

Since we are committed to quality, we perform various tests on the optimum processed materials based on the service environment. We are equipped with various instruments such as microhardness, accelerated aging (salt spray), wear and corrosion tests to examine the performance of the coatings in the similar service environment conditions.

We provide service and solution for almost all the components used in mining and mineral processing industries. We achieved positive solutions for restoring the components and surface modifications of the following metals/alloys.

- Carbon steel

- Stainless steel

- Cast Iron

- Aluminium

We examine the components using our In-house Research and Development laboratory and choose the process and coating materials based on the service environments. Our unique approach toward the problem, makes us outstanding in the field. If you have a problem which causes frequent and long downtime, please contact us to identify the causes for failure, find the best solution to improve the performance of your components and reduce downtime.