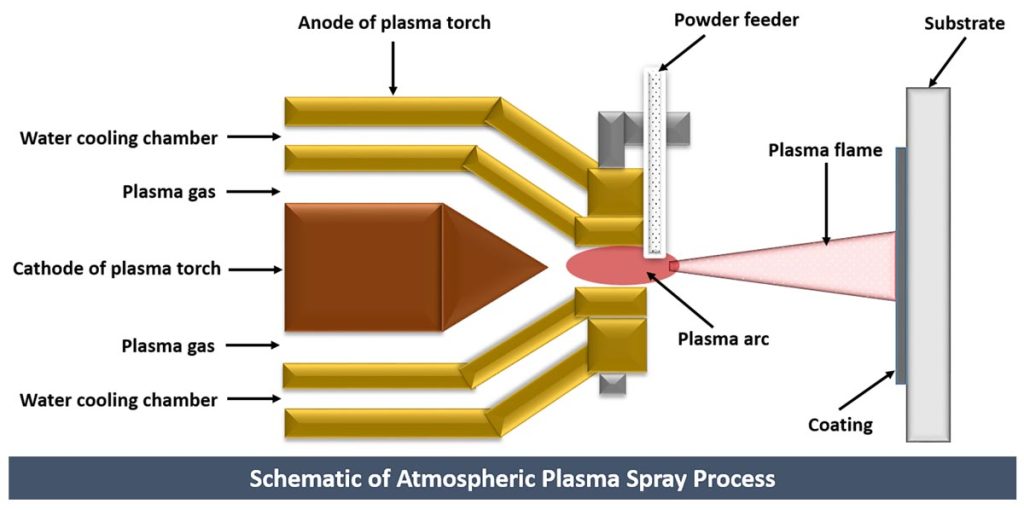

Various metals, alloys, high melting-point materials, such as ceramics and cermets in powder form or wire can be coated on different substrates using the plasma spraying process. The powders/wire materials are melted at over 10,000°C (depending on the process parameter) and sprayed onto the substrates using a plasma jet.

Why Plasma Spray

- Most versatile and flexible thermal spray process which covers a wide range of coating materials (metals, ceramics and alloys) on any substrate materials (glass, metals, ceramics and composite materials)

- Broad range of powder particle sizes can be used 5-100µm in the plasma spray which removes the challenging powder size requirements compared to other syste

- A high temperature is produced from the Plasma jet, which makes it suitable for cladding any high melting temperature materials such as refractory metals, ceramics and cermets

Plasma Spray can be performed on the following components (but not limited to)

- Mining equipment which requires extremely high-wear resistance

- Mineral processing equipment which is used in highly corrosive and erosive-corrosive environments

- Engine

- Transmission

- Brake / Driveline

- Oil & Gas

- Pumping

- Valves and valve seats

- Anti-Fouling Coatings, Anti-Skid Decking, Propellers and Shafts for marine environment

- Hydraulics

- Gas Turbine, Hydroelectric Turbine and Steam Turbine Components

We perform a wide range of material coatings using Atmospheric Plasma Spraying (APS) on many substrate materials to improve the wear, erosion-corrosion and galling resistance for extreme environments.

Please contact us to improve the performance of your components and reduce downtime using our APS coating facility.