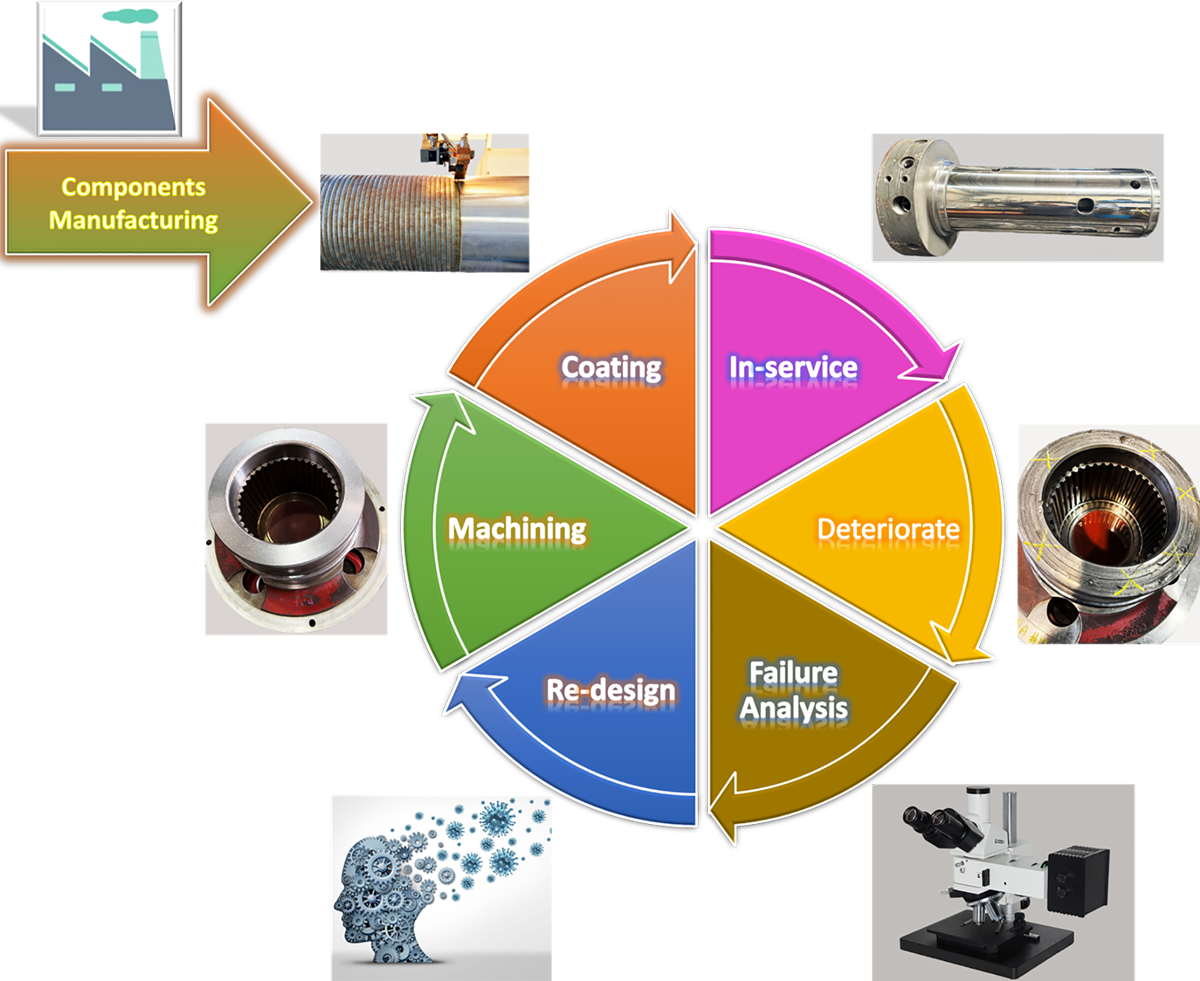

Arc Spray Engineering delivers turnkey restoration solutions for mining, mineral‑processing and oil & gas components across Australia since 2011. Using a range of in‑house repair techniques, we select the optimal process for each job—restoring parts to OEM condition or improving them for longer service life.

We’re committed to quality, strict timelines and ongoing R&D, ensuring reliable outcomes that reduce downtime and deliver excellent value for money. Our continual improvement programs and dedicated R&D lab keep us at the leading edge of surface modification, repair and remanufacture technologies.

Clients range from single operators and regional workshops to major mining, oil & gas and engineering companies. We welcome new challenges and tailor our services to meet each client’s specifications, safety requirements and schedule.

Contact Arc Spray Engineering to discuss your component restoration needs or request a quote—fast, professional and competitively priced solutions.