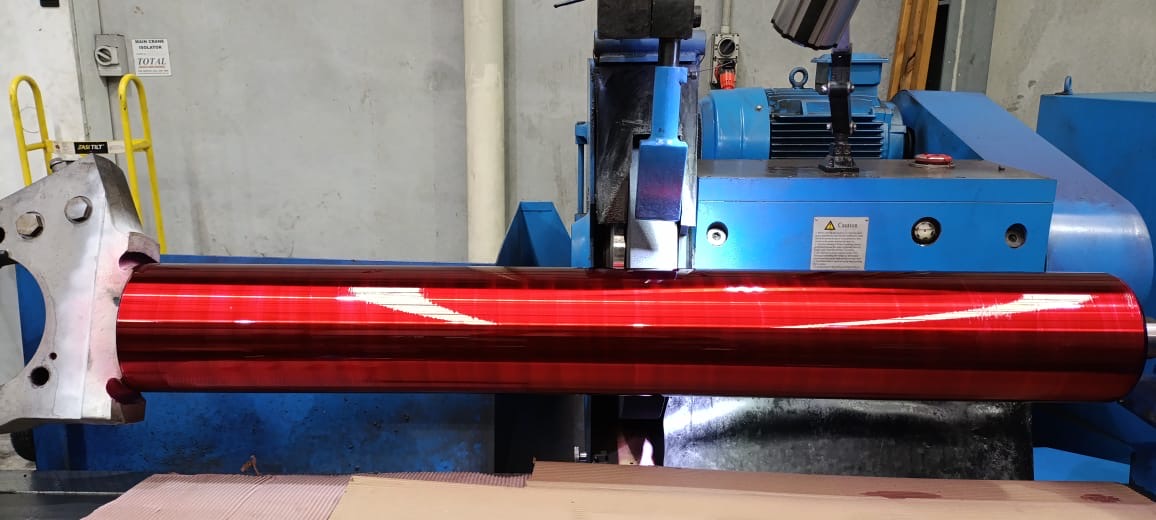

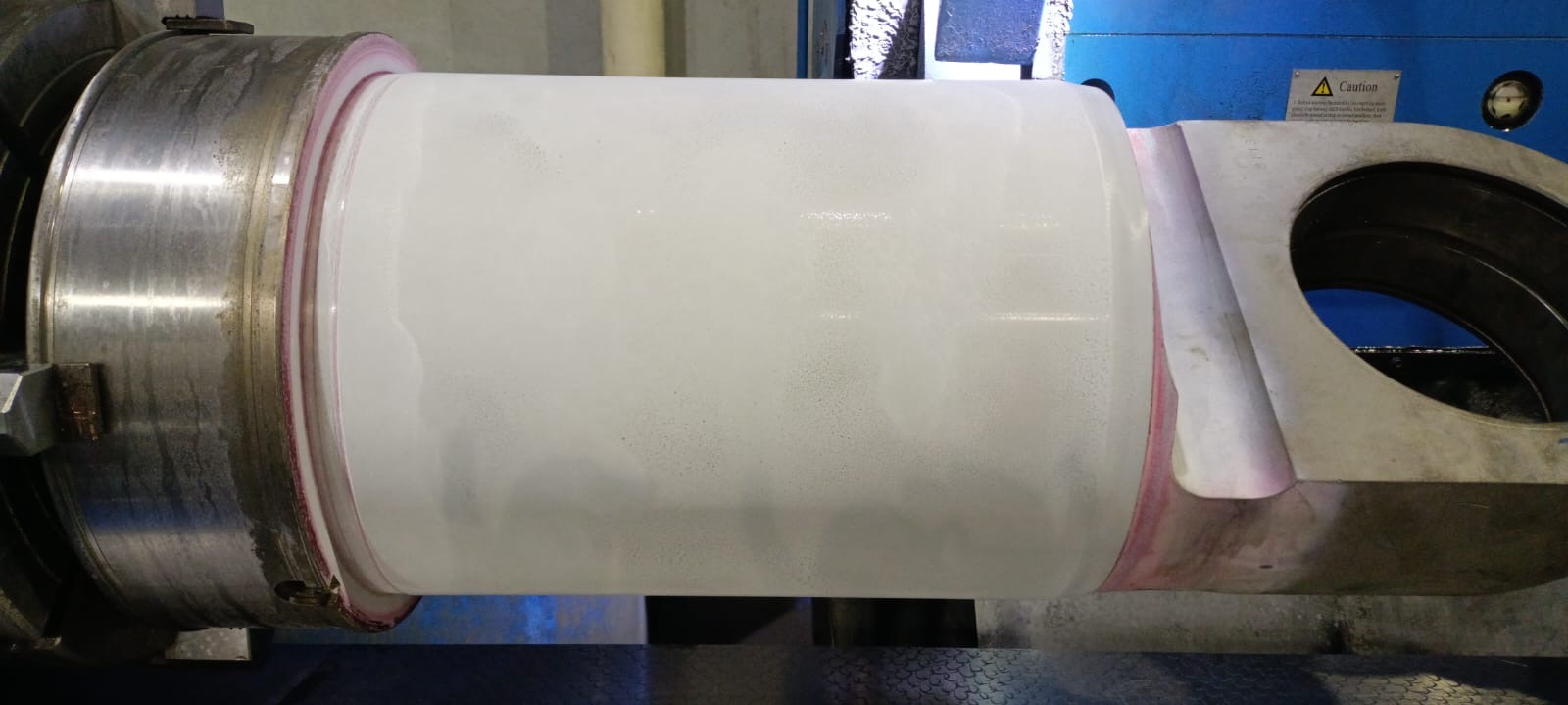

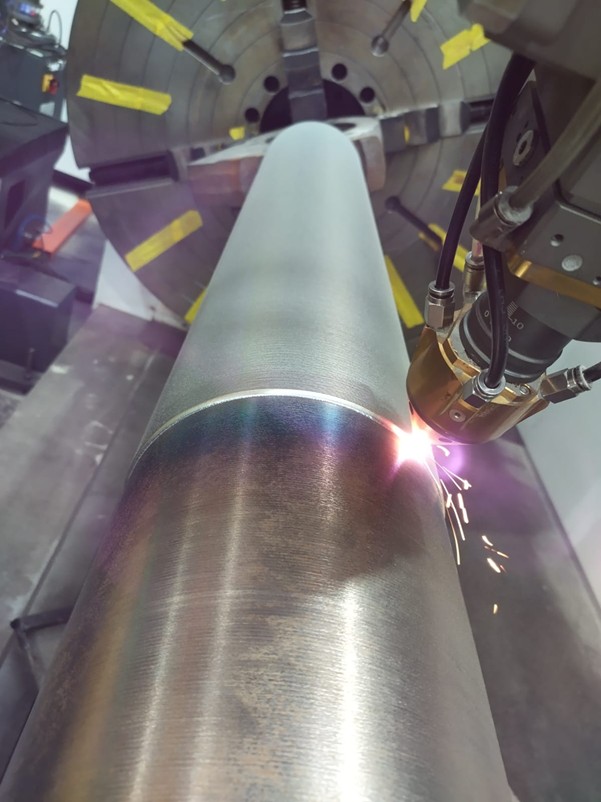

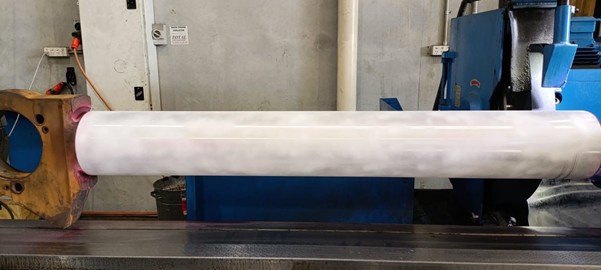

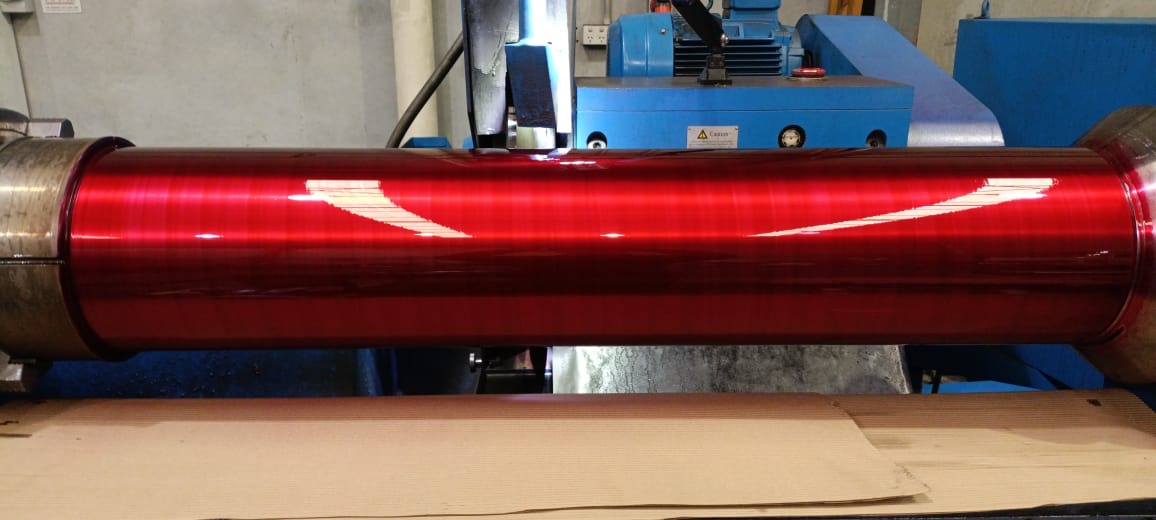

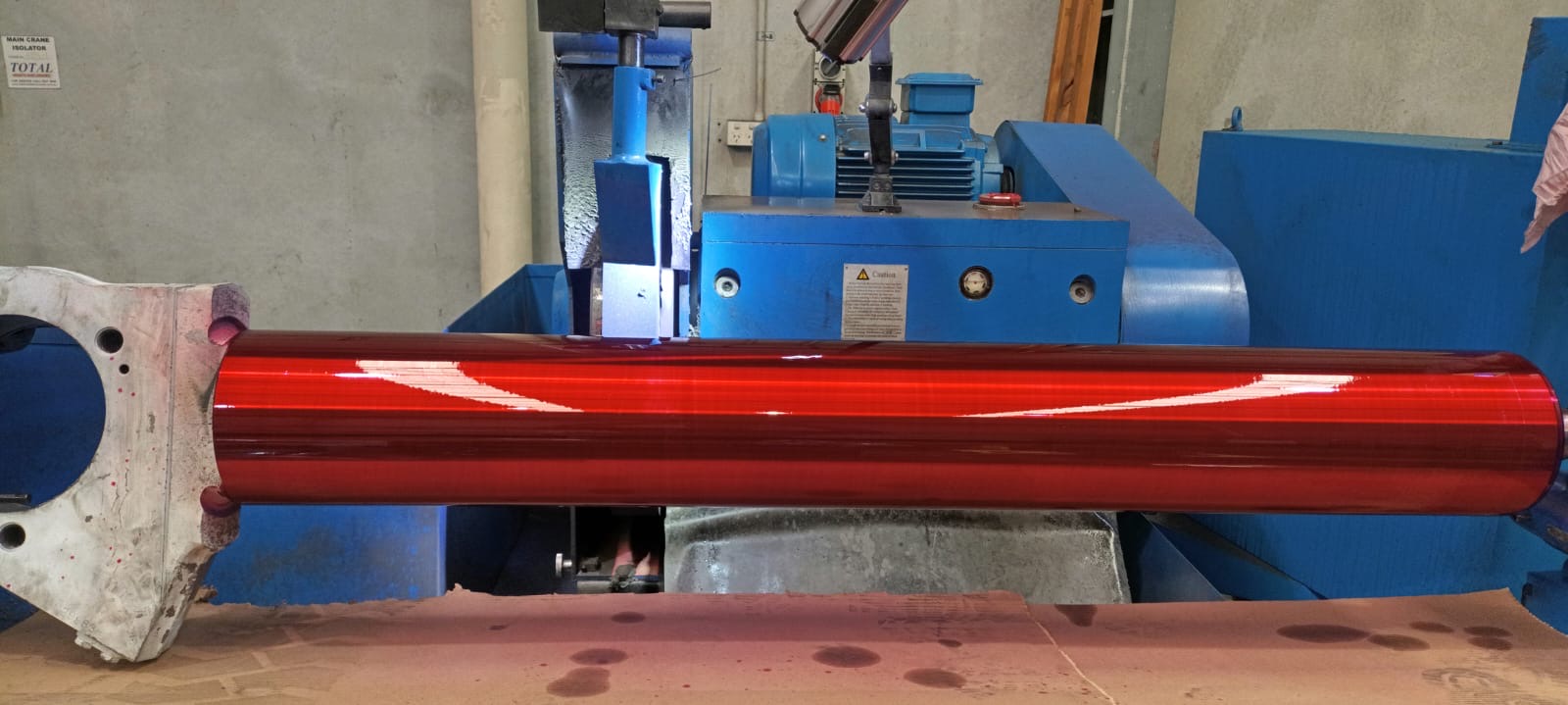

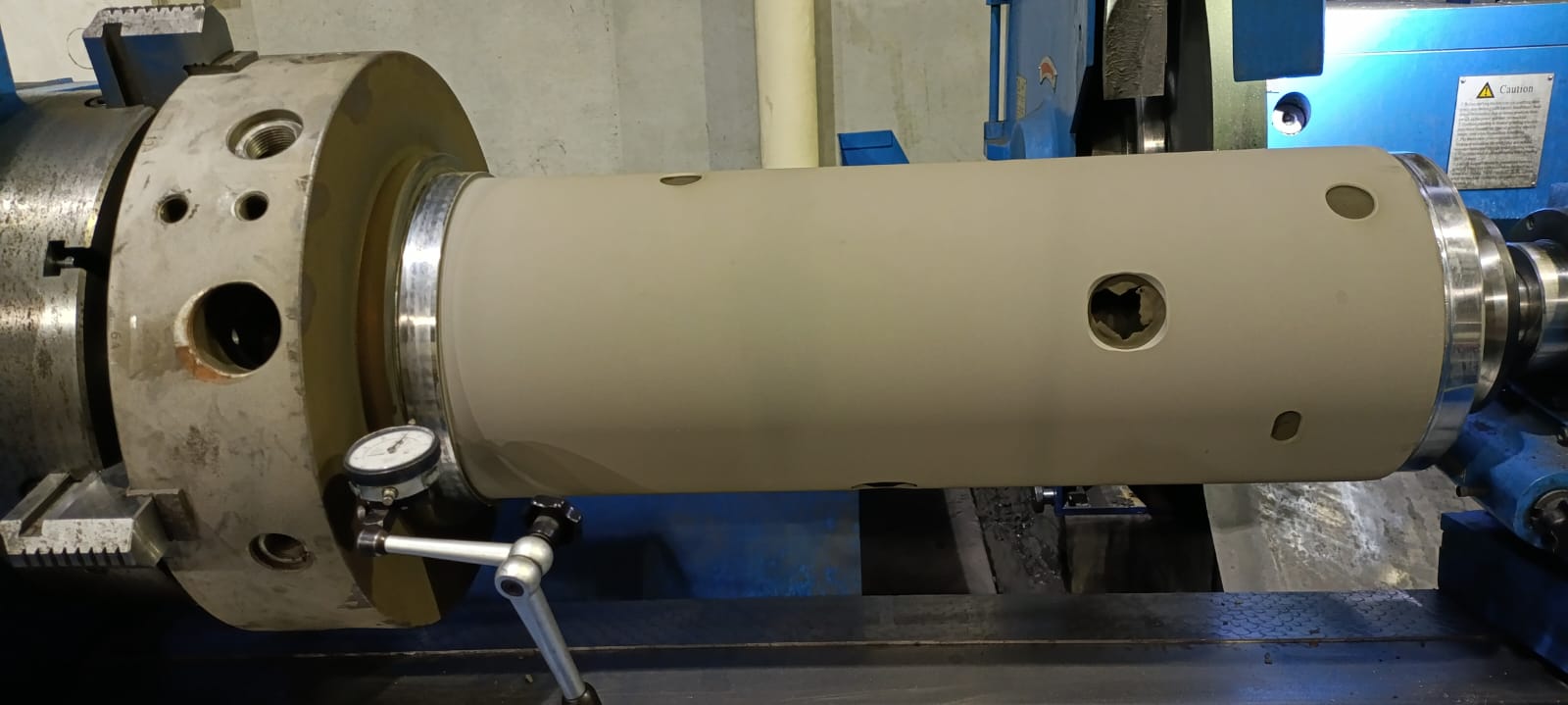

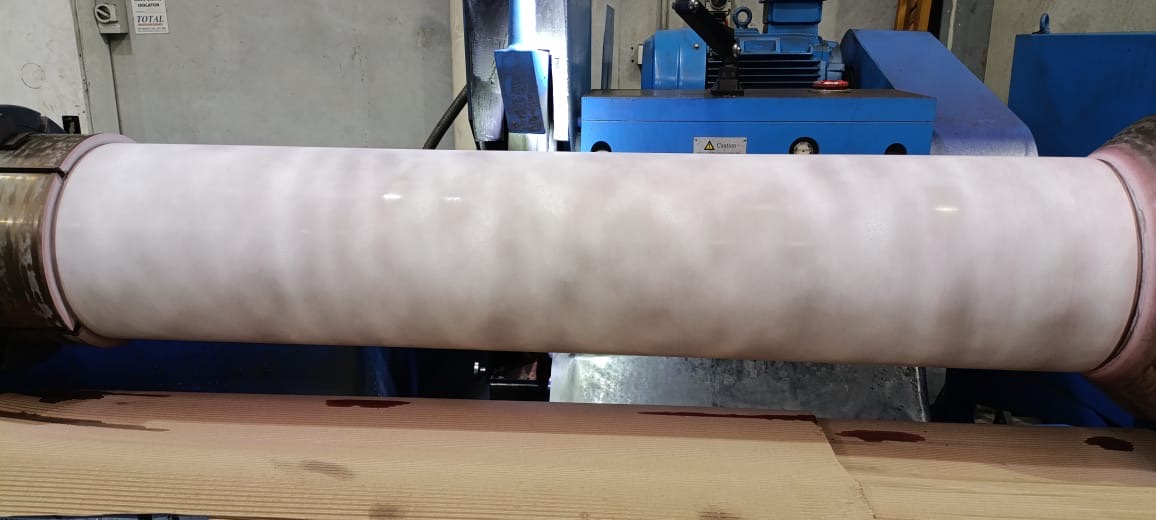

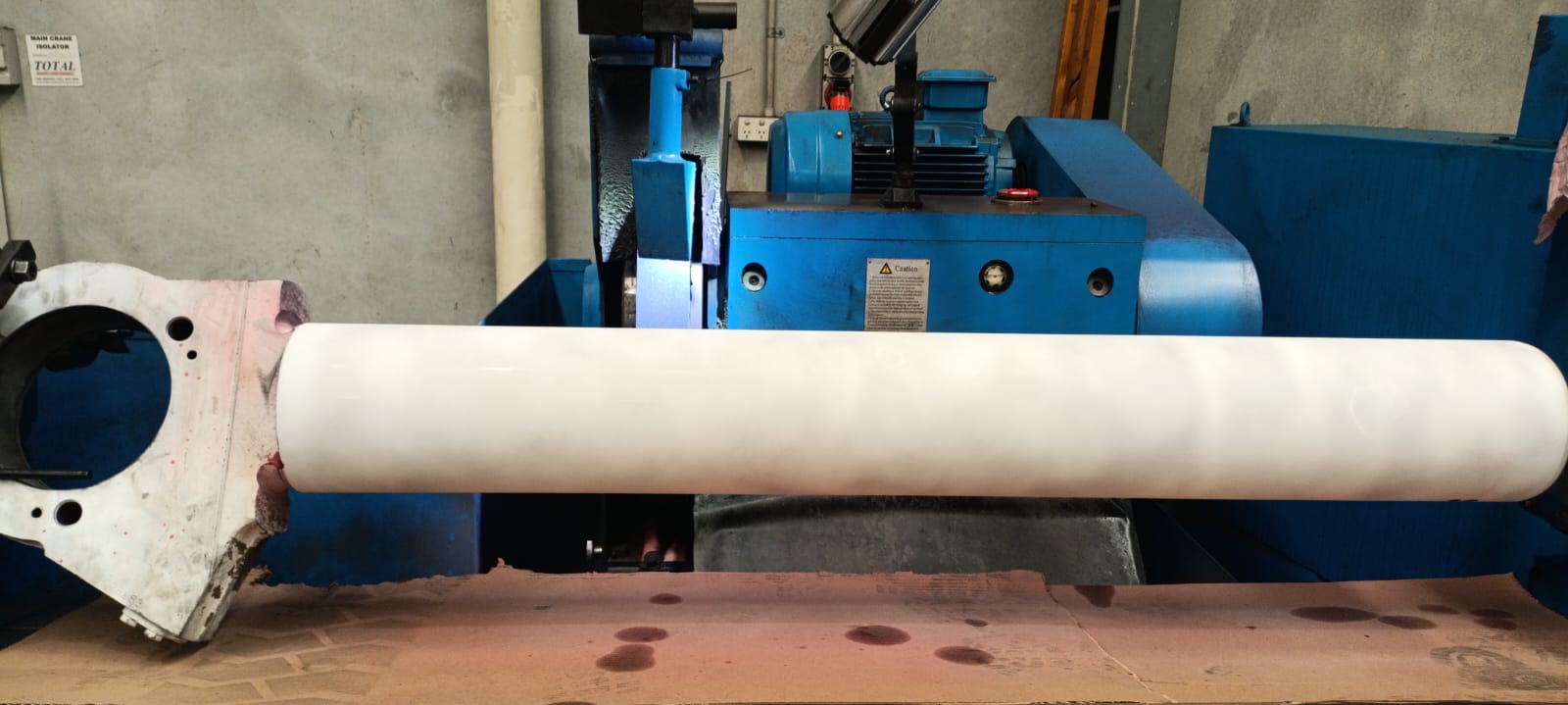

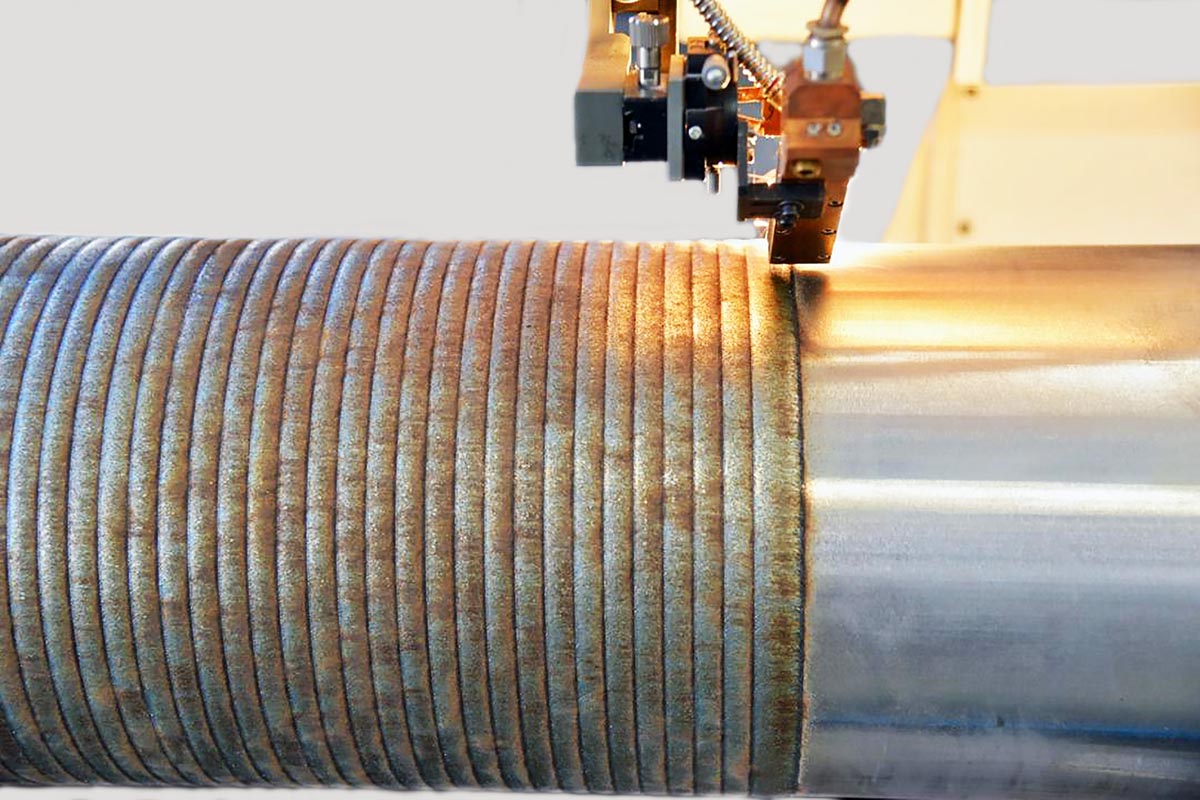

Laser cladding is a cutting-edge solution that outperforms both chrome plating and HVOF coatings, giving your components longer life, enhanced protection, and lower maintenance costs. Unlike thin coatings that can crack, chip, or peel under impact or bending, laser cladding fuses a thick, high-performance alloy directly into the base material, creating a metallurgical bond that moves with the substrate.

This means your equipment can withstand rock strikes, repeated bending, and heavy wear without failure, keeping operations running smoothly and reducing the need for frequent repairs. On top of that, the process is clean and environmentally safe, with no toxic chemicals or regulatory concerns. While traditional coatings may appear cheaper upfront, laser cladding delivers superior durability and reliability, paying for itself many times over by minimizing downtime, repair cycles, and replacement costs.

⚙️ Laser Cladding vs. Chrome Plating

| Feature | Laser Cladding | Chrome Plating |

|---|---|---|

| Bonding | Metallurgical bond (fused to base metal) | Mechanical/electrolytic adhesion only |

| Coating Thickness | 0.5 – 2+ mm (thick, durable) | 20 – 200 µm (thin, prone to cracking) |

| Materials | Wide range of alloys (Inconel, Stellite, stainless, tool steels) | Limited to chrome |

| Wear Resistance | Excellent – high hardness + impact resistance | Good hardness but microcracks reduce durability |

| Corrosion Resistance | Alloy tailored for environment | Limited, can corrode if cracked |

| Repair Capability | Rebuilds worn parts back to size | Cannot restore significant wear |

| Environmental Impact | Clean, no toxic waste | Uses hexavalent chromium (toxic, carcinogenic) |

| Regulatory Risk | Fully compliant with global standards | Increasingly restricted worldwide |

| Cost | Higher upfront, lower lifecycle cost | Lower upfront, higher long-term cost |

| Service Life | 3–10x longer (depending on application) | Shorter, requires frequent rework/replacement |

⚙️ Laser Cladding vs. HVOF Coatings

| Feature | Laser Cladding | HVOF Coatings |

|---|---|---|

| Bonding | Metallurgical bond (fused to base metal) – fully integrated with the substrate, can flex and distribute stress during bending or impact, minimizing cracking or delamination | Mechanical/metallurgical bond (splat deposition) – adheres to surface roughness; high flex or bending can cause cracks, spalling, or peeling |

| Coating Thickness | 0.5 – 2+ mm (thick, durable) | 100 – 600 µm (thin to medium) |

| Materials | Wide range of alloys (Inconel, Stellite, stainless, tool steels) | Carbides, stainless, cobalt, NiCr alloys |

| Wear Resistance | Excellent – high hardness + impact resistance | High hardness, but thinner layers limit load-bearing capacity |

| Corrosion Resistance | Alloy tailored for environment | Good, depends on material and porosity |

| Repair Capability | Can rebuild worn or damaged parts to original dimensions | Limited – primarily for surface enhancement |

| Flexibility / Substrate Bending | Coating moves with substrate due to metallurgical bond; minimal cracking under repeated flexing | Brittle layer may crack or spall under bending; reduced structural tolerance |

| Environmental Impact | Clean, no toxic waste | Safer than chrome plating, but produces fine dust/fume |

| Surface Finish | Typically requires finishing (machining, grinding) | Smooth finish possible directly |

| Heat Input | Localized, low distortion | High thermal spraying temperatures, can induce residual stress |

| Cost | Higher upfront, lower lifecycle cost | Moderate upfront, depends on material/thickness |

| Service Life | 3–10x longer (depending on application, impacts, and flexing) | Good, but thin coatings may fail under repeated impact or flexing |

✅ Key Takeaway (Impact & Flexibility Focus):

Laser cladding’s metallurgical bond ensures the coating flexes with the substrate, providing superior resistance to impact, bending, or flexing. HVOF coatings, while hard, are more brittle and can crack, chip, or peel under repeated stress or substrate deformation.