Services

In house Research and NDT Testing

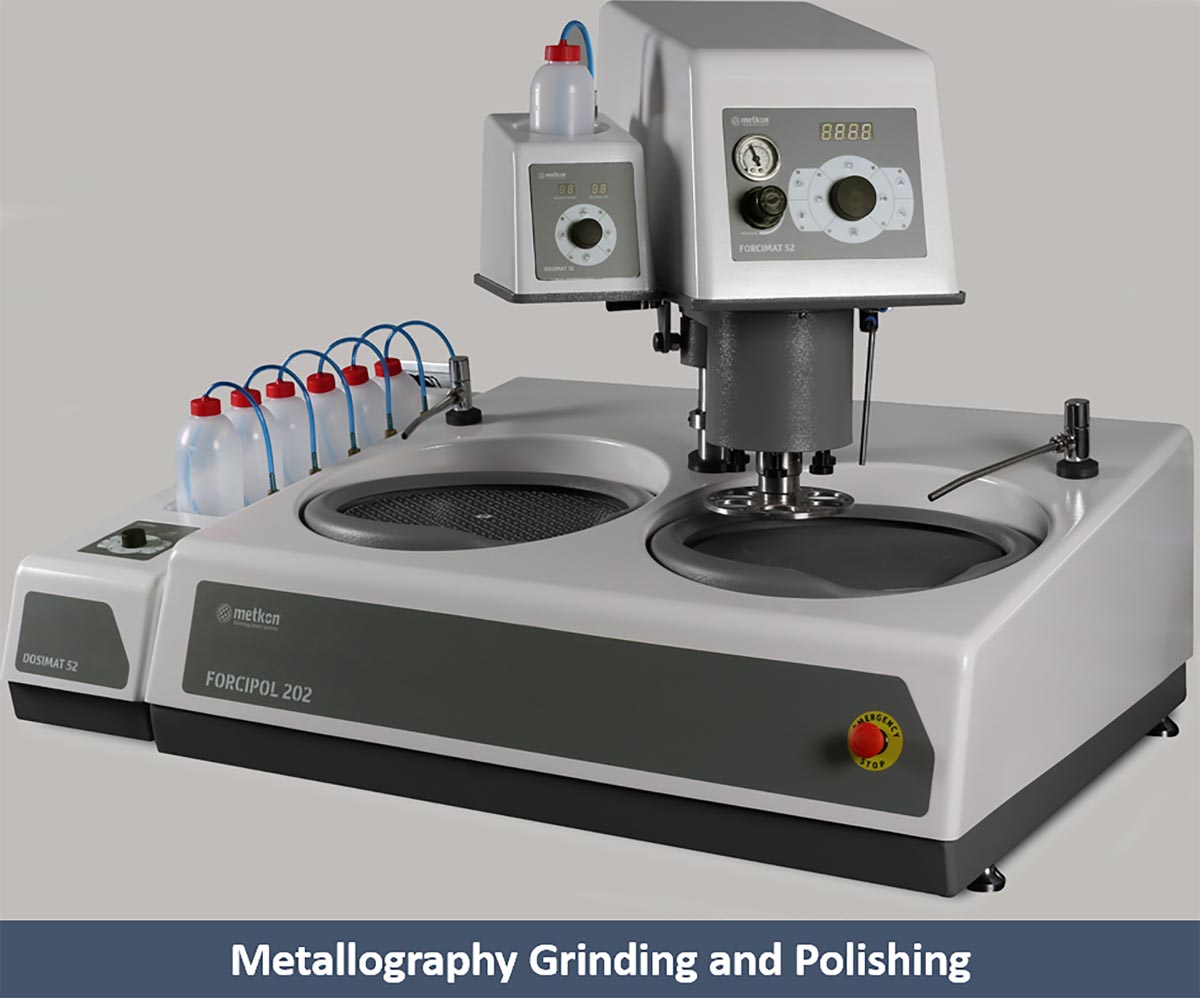

We follow a systematic scientific approach to perform any work in our industry. The in-house laboratory equipped with metallography analysis, performance tests and qualified experts can perform high quality research work to restore your components with improved performance for your service environment. We perform failure analysis, optimize the process and perform various test to find the best solutions.

Arc Spray Engineering provides accredited NDT services specialising in liquid penetrant (pen dye/PT) and magnetic particle inspection (MPI/MT). Our technicians are qualified to industry standards and perform both workshop and onsite inspections to rapidly detect surface and near‑surface defects in welds, castings, shafts, valves, flanges and structural components. We use calibrated equipment and HSE‑compliant procedures, delivering fast, traceable reports with clear pass/fail criteria. NDT is fully integrated into our repair workflow—pre‑repair assessment, in‑process verification and final sign‑off—ensuring component integrity, regulatory compliance and confidence in returned‑to‑service parts

Failure analysis

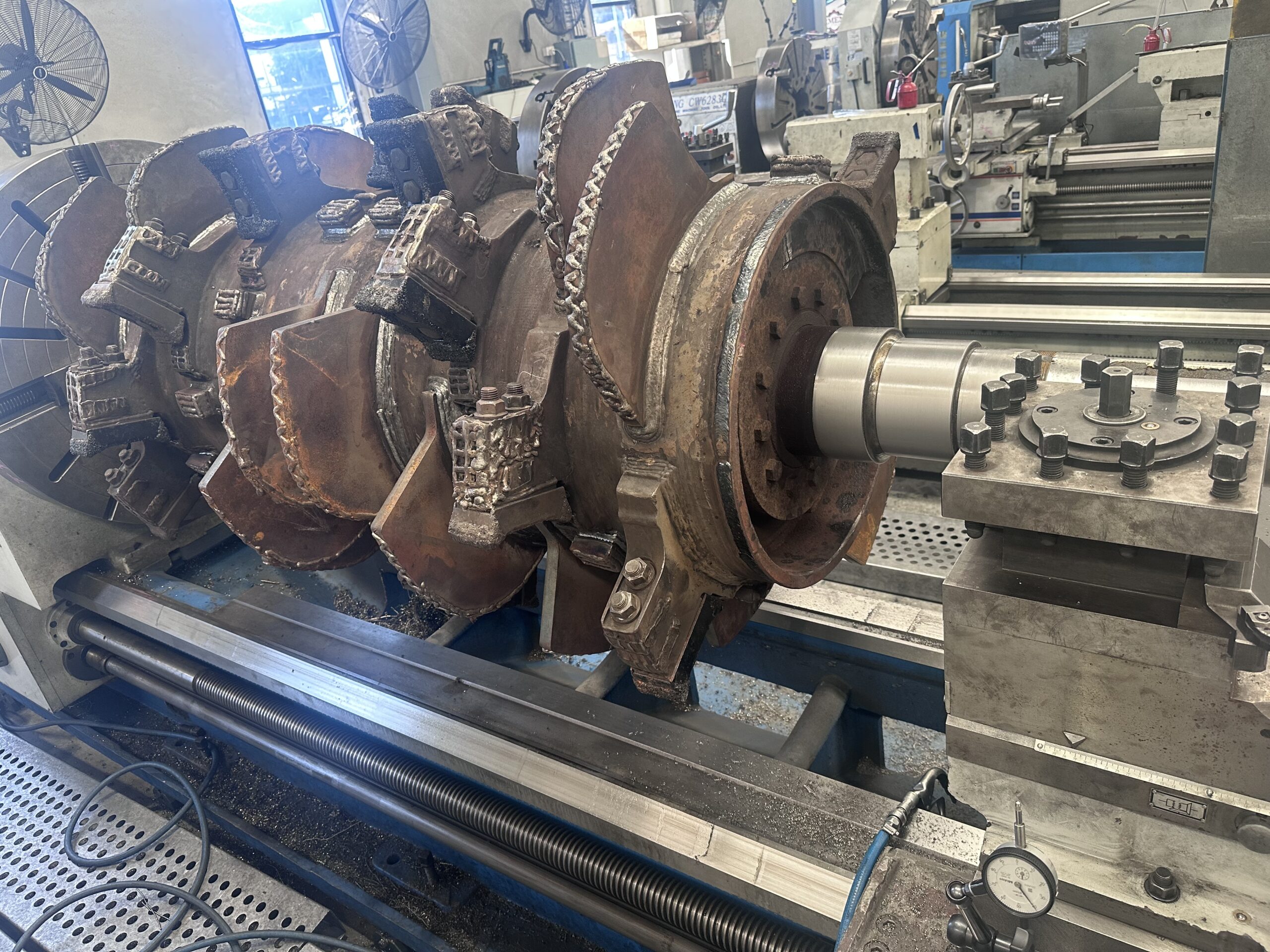

We inspect and analyse the cause of the failure before hypothesising the solution to avoid any further failure in the components.

For an example, we perform NDT techniques to identify the nature of defects such as cracks, porosity and analyse the fracture surface. We quickly perform chemical composition and metallography analysis to identify any change in microstructural morphology and phase which could cause the failure.

Optimize the process and materials composition

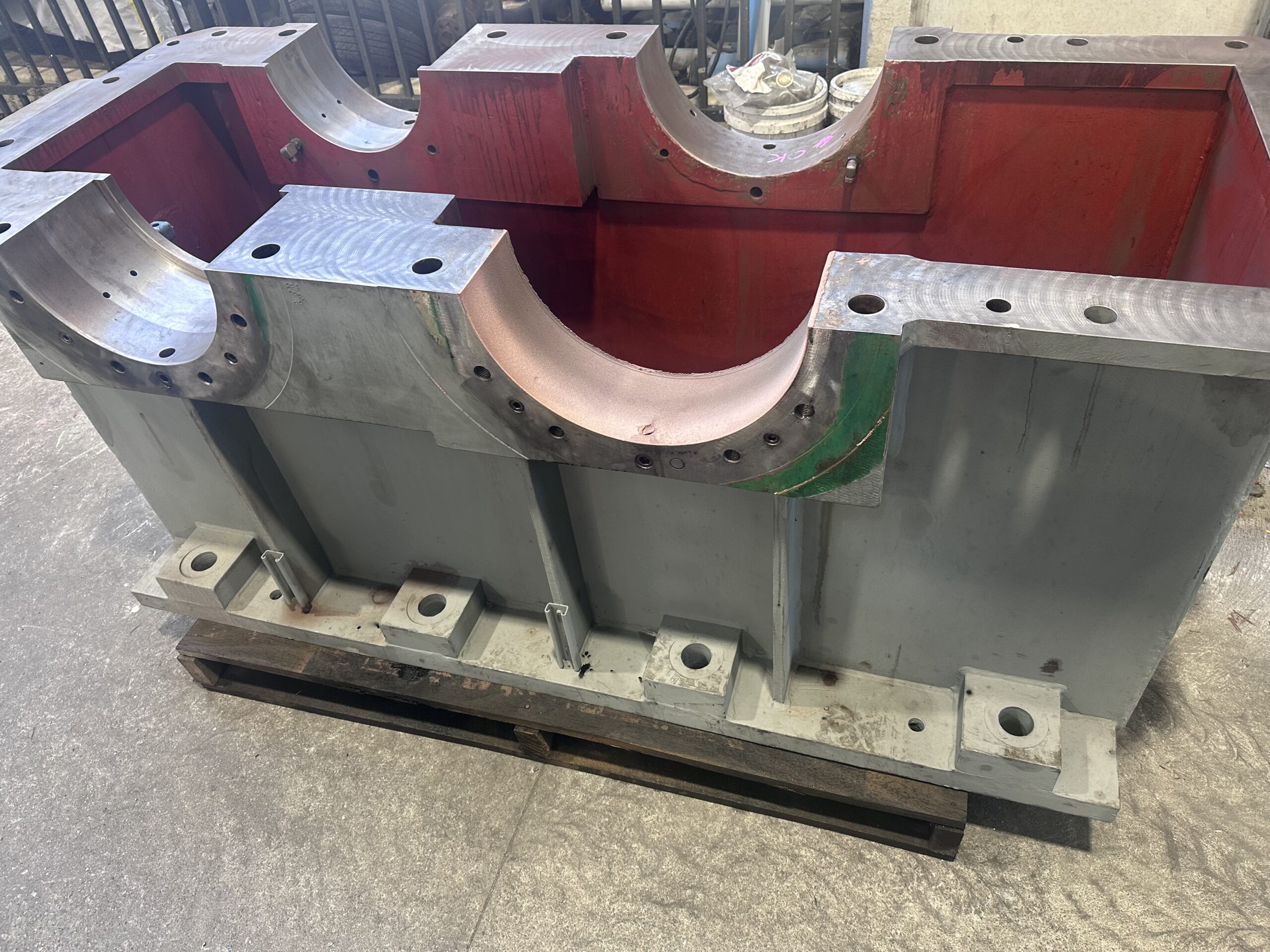

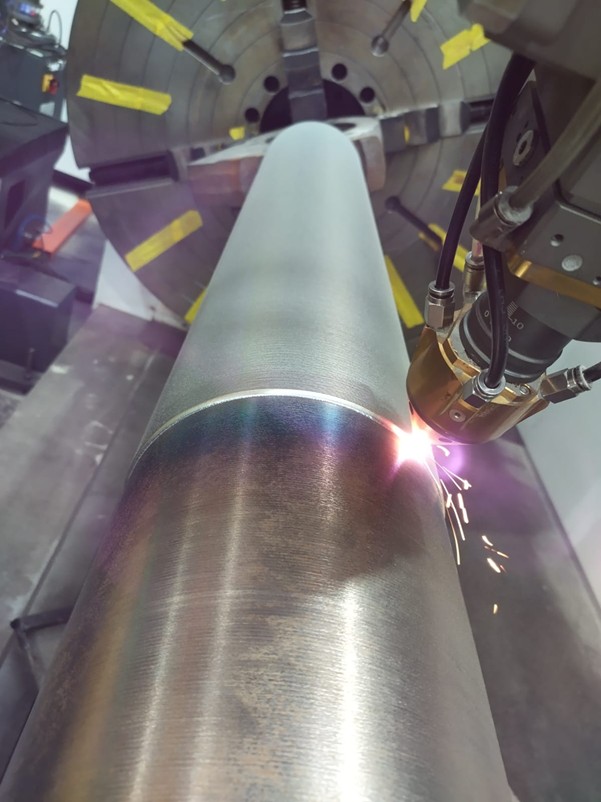

Based on the failure analysis, we work through the materials required for restoring the components for improved performance such as wear, corrosion, erosion-corrosion and galling resistance. Based on the requirements, we select the process from the range of equipment available in our workshop. We optimize the process condition to achieve desired coating thickness with minimum/no porosity and good metallurgical bonding with the substrate.

Performance testing

At Arc Spray Engineering, quality is built into every stage of our process. We conduct detailed testing on coating materials to ensure they perform reliably in the service environments our customers operate in. Our in-house laboratory is equipped with microhardness measurement, accelerated ageing (salt spray), and wear and corrosion testing systems, allowing us to validate coating performance under real-world conditions.

We support a wide range of components across the mining and mineral processing industries and have successfully restored and upgraded parts manufactured from:

-

Carbon steel

-

Stainless steel

-

Cast iron

-

Aluminium

Each component is assessed in our in-house Research and Development laboratory, where we determine the optimal repair method and select the most suitable coating materials based on operating conditions. Our engineered, problem-solving approach allows us to deliver reliable, long-life solutions that reduce downtime and extend equipment performance.

If recurring failures or excessive downtime are impacting your operation, we can help. Our team will diagnose the root cause, recommend the best surface-engineering solution, and restore your components to a higher, more durable standard.

Get in touch today