Why Choose Laser Cladding?

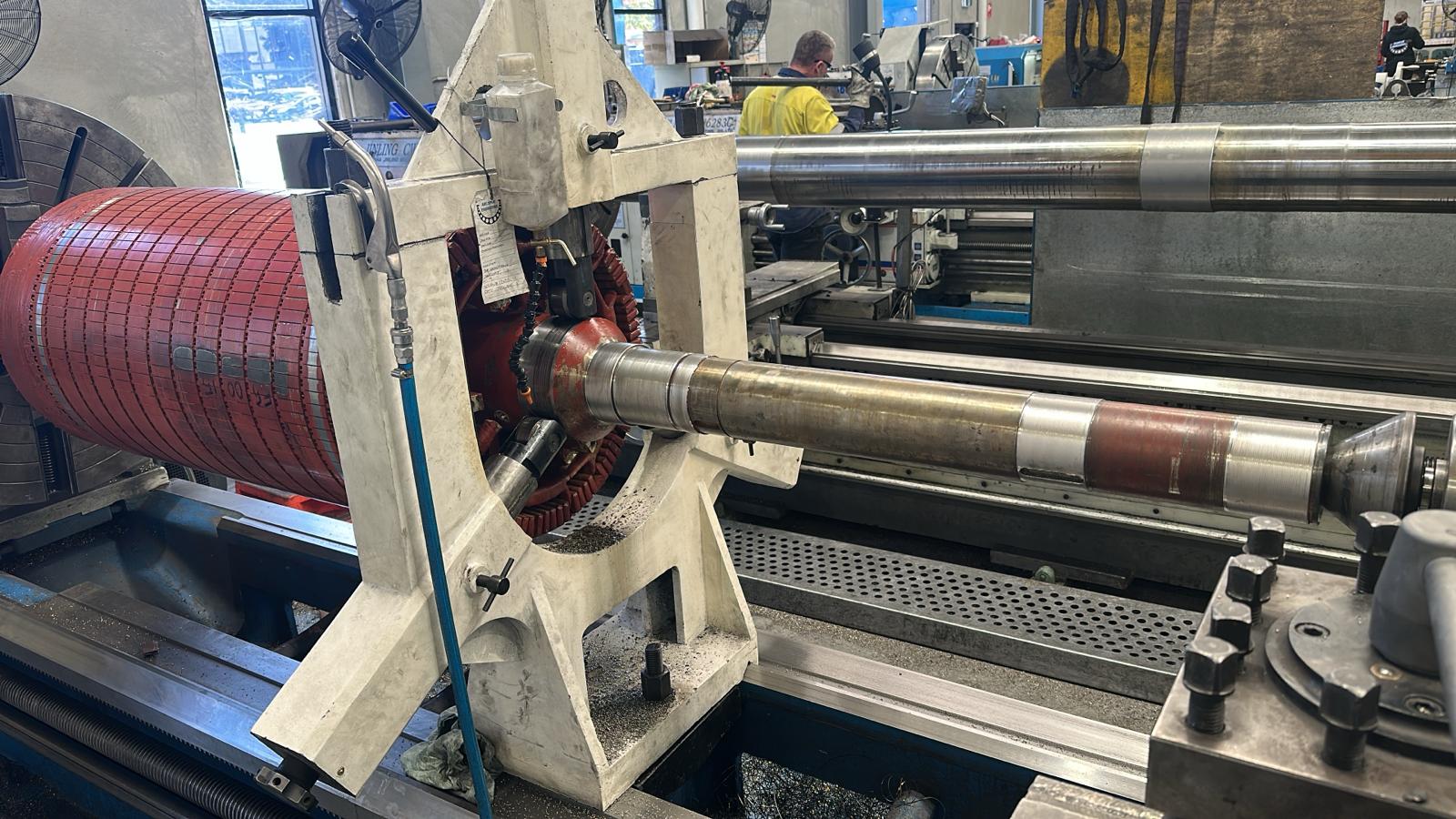

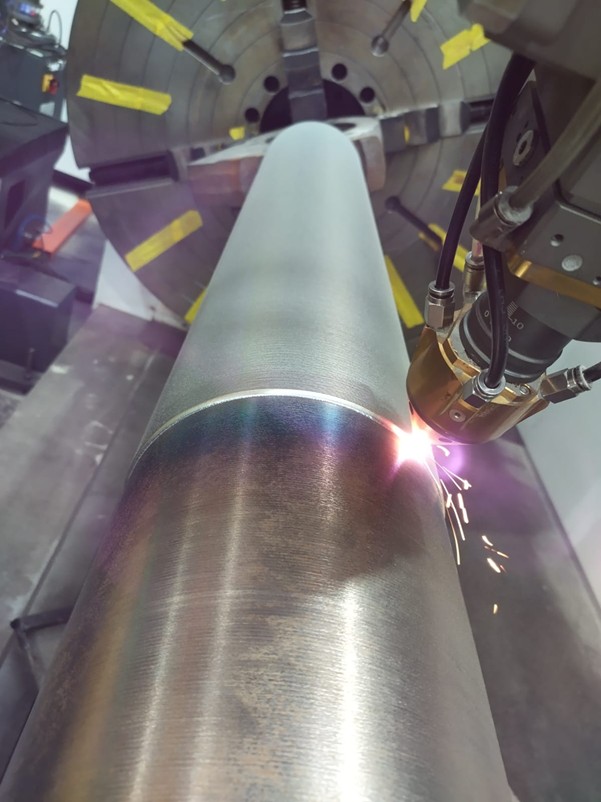

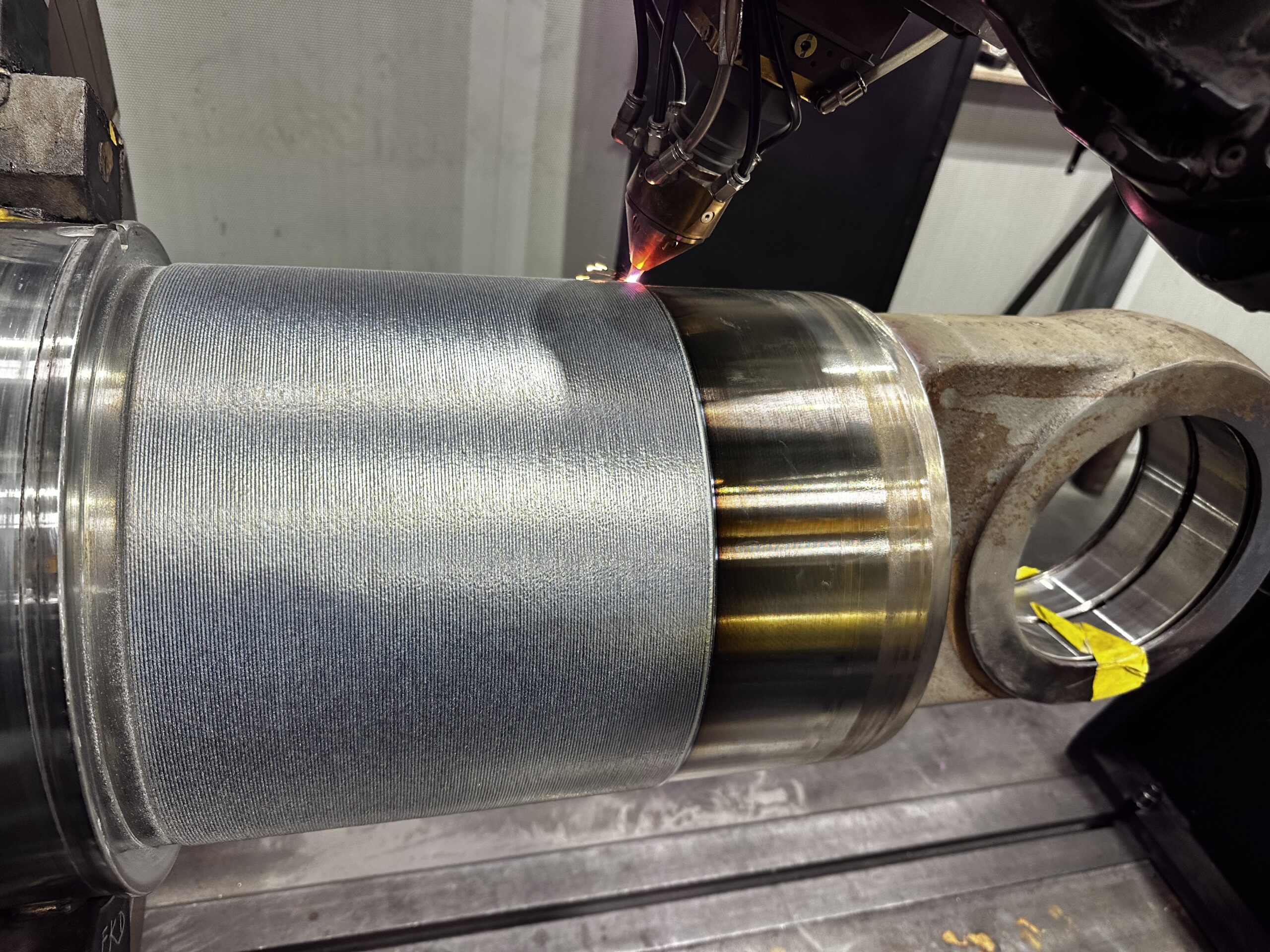

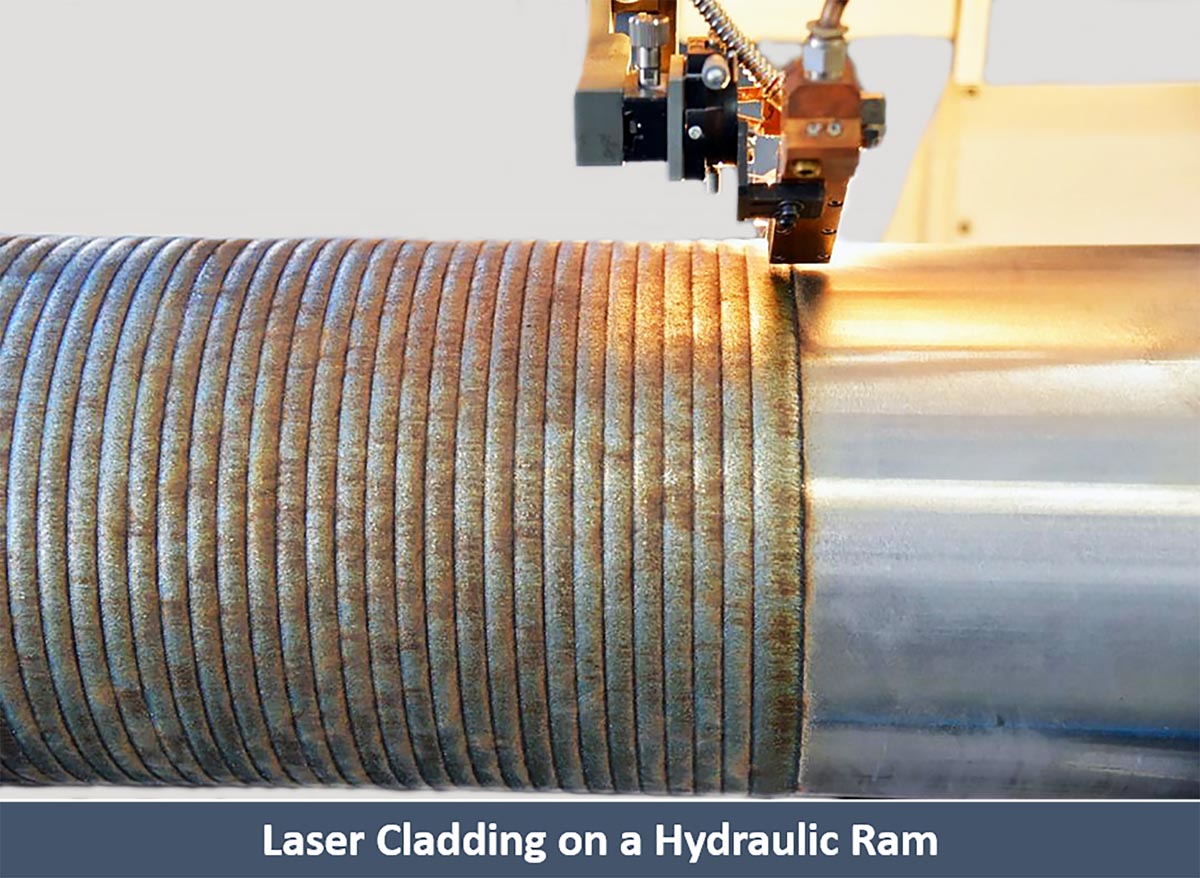

Laser cladding is one of the most advanced repair and surface protection technologies available today. By fusing a high-performance alloy directly into the base material with a highly focused laser beam, we deliver repairs and coatings that are stronger, longer lasting, and more precise than traditional methods.

Key Advantages of Laser Cladding:

✅ Low Dilution, High Purity – The concentrated laser creates clean, pure cladding with minimal mixing into the base material.

✅ One-Pass Results – A single layer can achieve the required hardness, microstructure, and chemistry — saving time and cost.

✅ Minimal Heat Input – The small heat-affected zone protects the original material, avoiding distortion and preserving mechanical properties.

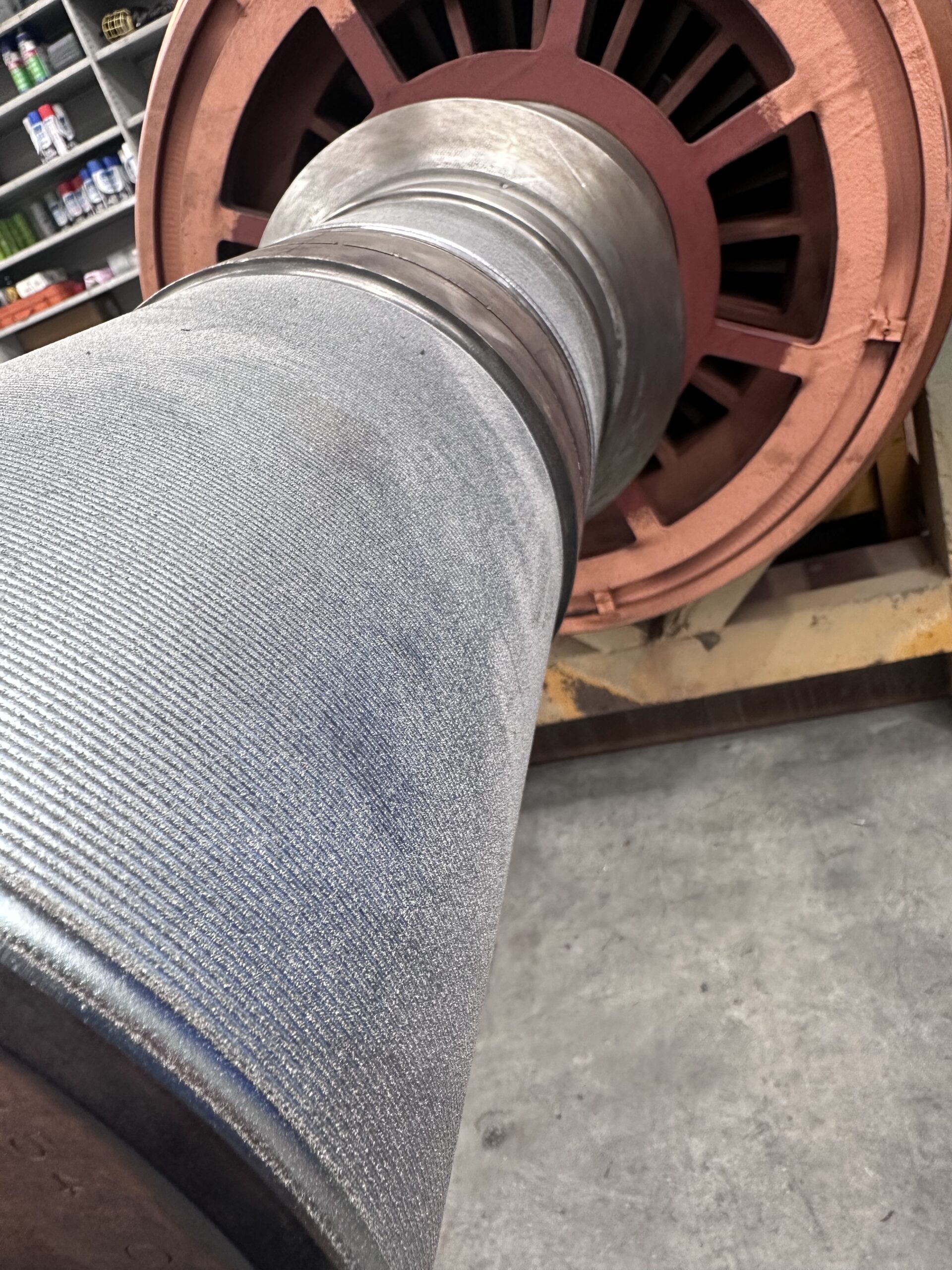

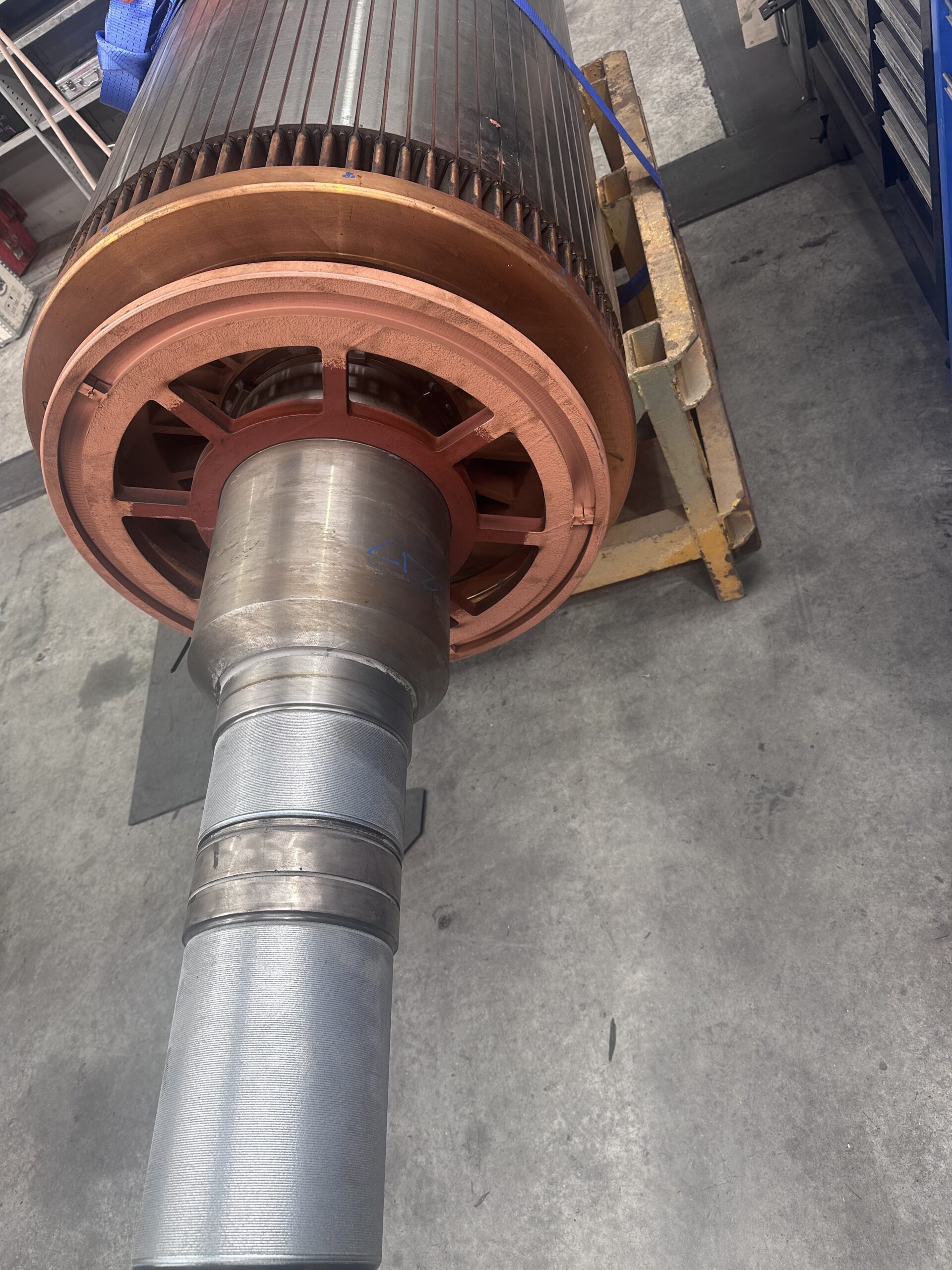

✅ Dimensional Accuracy – Parts maintain OEM dimensions and close tolerances, reducing or eliminating the need for post-machining.

✅ Superior Metallurgical Bonding – Unlike thermal spray coatings, laser cladding fully fuses with the substrate, resisting cracking, spalling, and delamination under heavy load or impact.

✅ Impact & Flex Resistance – With metallurgical bonding, the clad layer withstands rock strikes, vibration, and substrate flexing without failure.

✅ Corrosion & Wear Protection – Dense, crack-free, and porosity-free layers keep out corrosive liquids and gases, preventing catastrophic damage.

✅ Custom Alloys On-Demand – Elemental powders can be mixed in-situ, enabling tailored alloys for your specific operating environment.

Our Capabilities

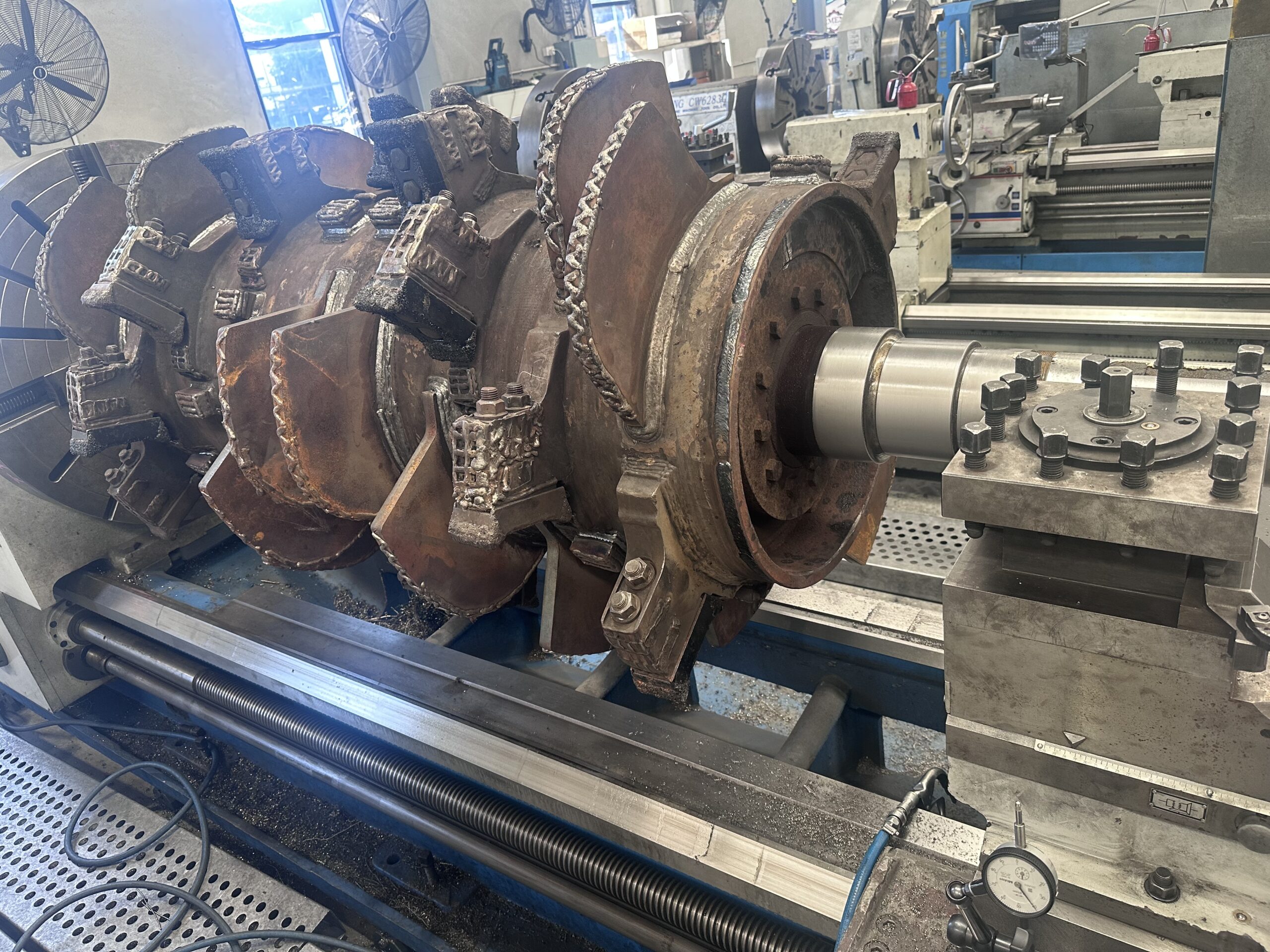

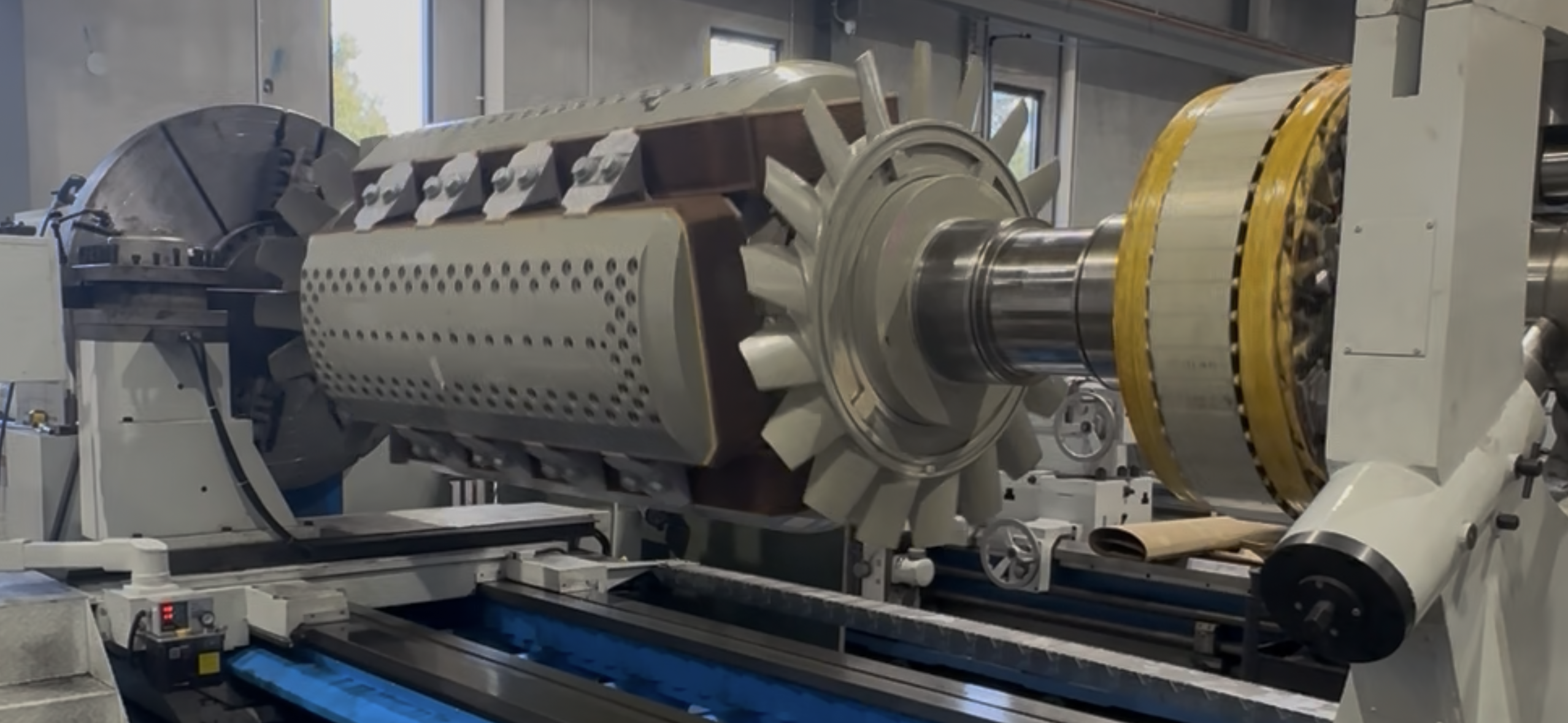

Arc Spray Engineering operates high-power horizontal and vertical laser cladding systems with robotic arms — designed to tackle even the most challenging and critical repairs with precision and repeatability.

Applications

Laser cladding is ideal for industries and components where strength, wear resistance, and reliability are critical:

-

Mining equipment subject to extreme abrasion

-

Mineral processing components exposed to corrosion and erosion

-

CAT, Komatsu, Hitachi, Liebherr OEM Earthmoving parts

-

Engines & transmissions

-

Driveline & braking components

-

Oil & gas equipment

-

Pumps, valves, and valve seats

-

Bearing and seal journals (OD & ID)

-

Coal and ore crushing equipment

-

Intricate or high-value component restoration

Let’s Extend the Life of Your Equipment

At Arc Spray Engineering, our goal is simple: reduce your downtime, cut repair costs, and keep your equipment running longer.

📞 Contact us today to find out how our laser cladding services can improve performance and reliability in your operation.