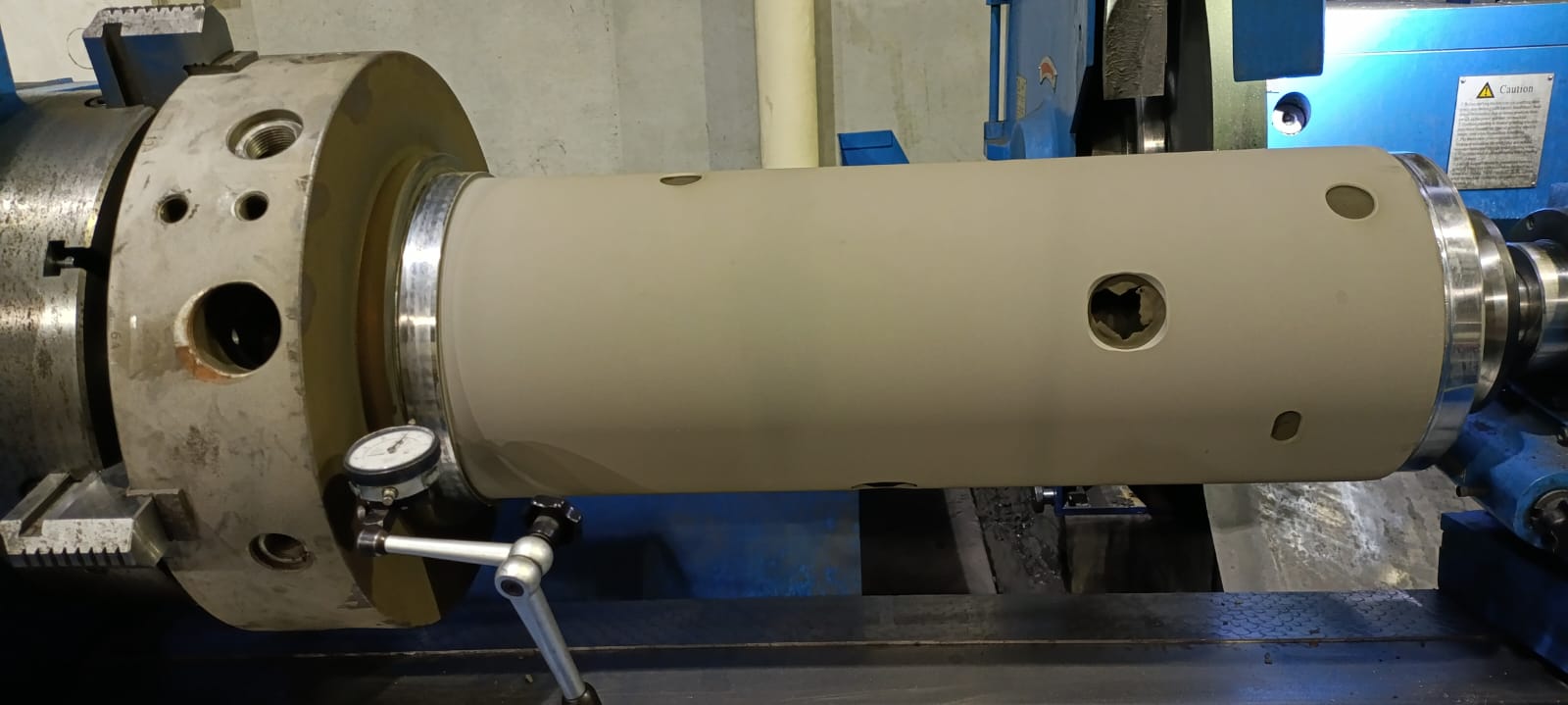

🛡️ Chrome Oxide APS Coatings for Pump Components

Chrome oxide (Cr₂O₃) coatings applied by Atmospheric Plasma Spraying (APS) are one of the most effective ways to extend the service life of pump components. By combining extreme hardness with chemical inertness, these coatings protect against both abrasive wear and corrosive attack — the two leading causes of pump failures.

✅ Key Advantages of Chrome Oxide APS

-

High Hardness & Abrasion Resistance – Resists particle erosion, cavitation, and slurry wear, keeping impellers, sleeves, and shafts in service longer.

-

Superior Corrosion Protection – Chemically inert in acids, salts, and oxidizing environments, preventing pitting and premature failure.

-

Low Porosity, High Integrity – Dense coatings with <2% porosity block fluid ingress; sealing options further enhance protection.

-

Dimensional Stability – Builds strong, uniform layers that can be ground and polished back to OEM tolerances.

-

Extended Service Intervals – Reduces unplanned maintenance and replacement costs by significantly increasing component life.

⚙️ Applications

Chrome oxide APS coatings are particularly effective in pumps operating in harsh, abrasive, or corrosive environments, including:

-

Slurry pumps handling sand, ore, or mineral particles

-

Chemical process pumps exposed to aggressive fluids

-

Marine pumps (saltwater corrosion & cavitation resistance)

-

Oil & gas pumping systems under erosive-corrosive duty

-

Power generation cooling water pumps

🚀 Proven Performance

Field experience and literature consistently show that APS Cr₂O₃ coatings can extend pump service life by 50% or more compared to uncoated components. With optimized parameters and sealing, wear and corrosion rates are dramatically reduced — keeping pumps in service longer and lowering lifecycle costs.

📞 Let’s Protect Your Pumps

At Arc Spray Engineering, we apply chrome oxide APS coatings tailored to your operating environment, ensuring maximum wear and corrosion resistance.

📞 Contact us today to learn how our coatings can extend the life of your pump components and reduce maintenance downtime.