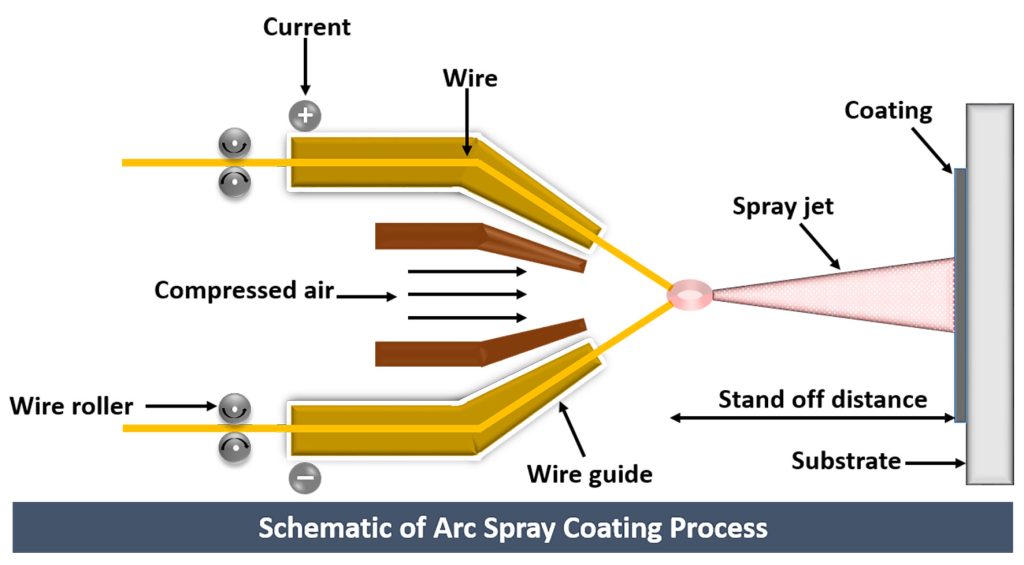

Arc spray is one of the thermal spraying processes most commonly used in the world. The arc spray process uses an electric arc to melt the two consumable coating feedstocks, the molten materials is projected using high velocity gas stream then upon contact solidifies and mechanically bonds on the target substrate.

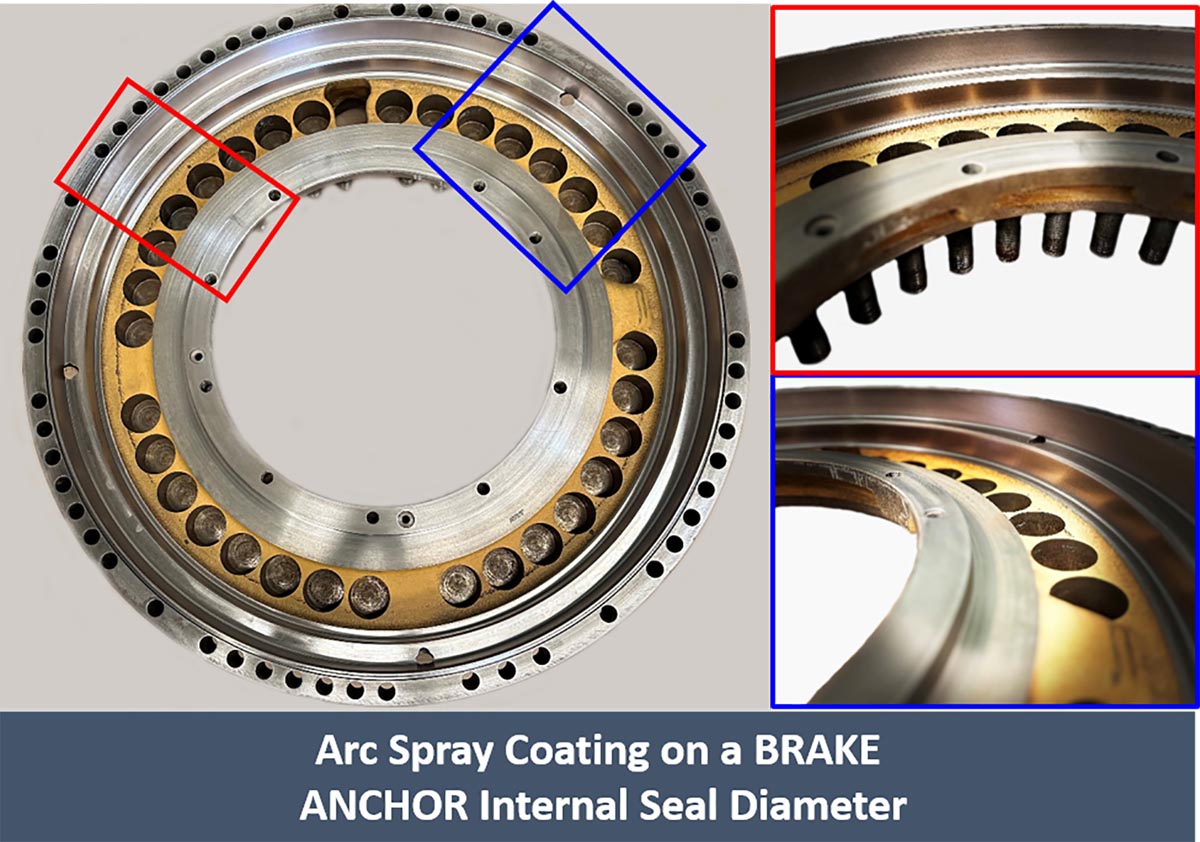

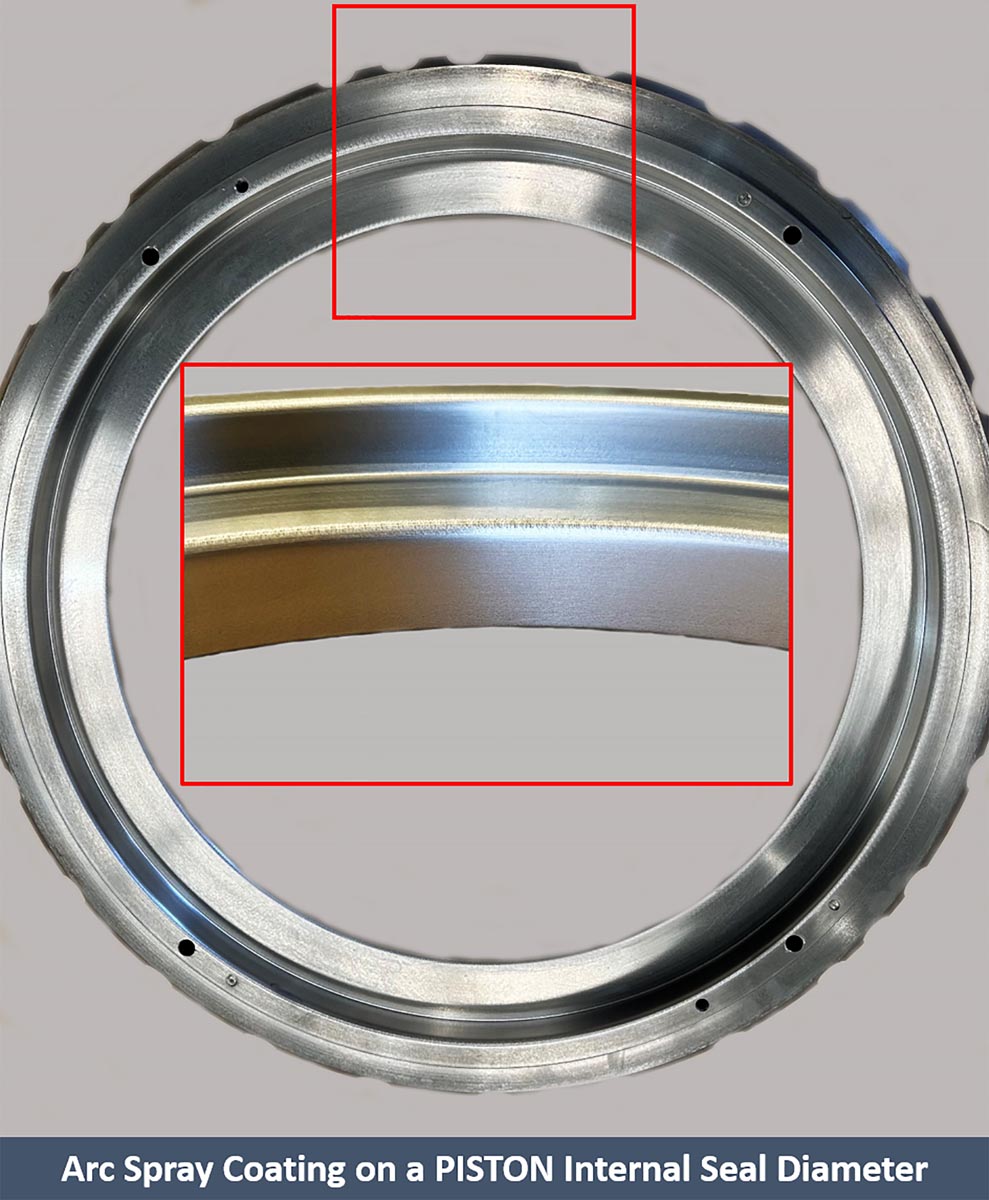

We perform Arc Spray coating on a wide variety of materials to restore the components to their original condition based on our clients need. With continuous R&D, we aim to improve the wear, corrosion, erosion-corrosion and heat resistance for the components used in Mining and Mineral Processing industries.

Why Arc Spray

- Low energy consumption which reduces the cost of the process: Arc spray only uses compressed air and electricity

- Minimal heating of the substrate leads to low material distortion

- Porosity can be minimized with optimized process parameters

- Since Arc spray process uses two separate wires, custom alloys coating can be produced easily through feeding different wire materials

- Sacrificial corrosion coating can be made uniformly on the surface of steel using Aluminium and Zinc-Aluminium alloys arc spray coating instead of tradition hot dip galvanizing and electroplating methods

- Fewer health and safety risks due to simple process – Low energy requirement, no consumption of harmful gas or fine metallic powders

Arc Spraying can be performed on the following components (but not limited to)

- Mining equipment which requires wear resistance

- Mineral processing equipment which is used in corrosive and erosive-corrosive environments

- Engine

- Transmission

- Brake / Driveline

- Oil & Gas

- Pumping

- Galvanizing for steel

Please contact us to improve the performance of your components and reduce downtime using our arc spray coating facility.